» Products » stainless steel round bar

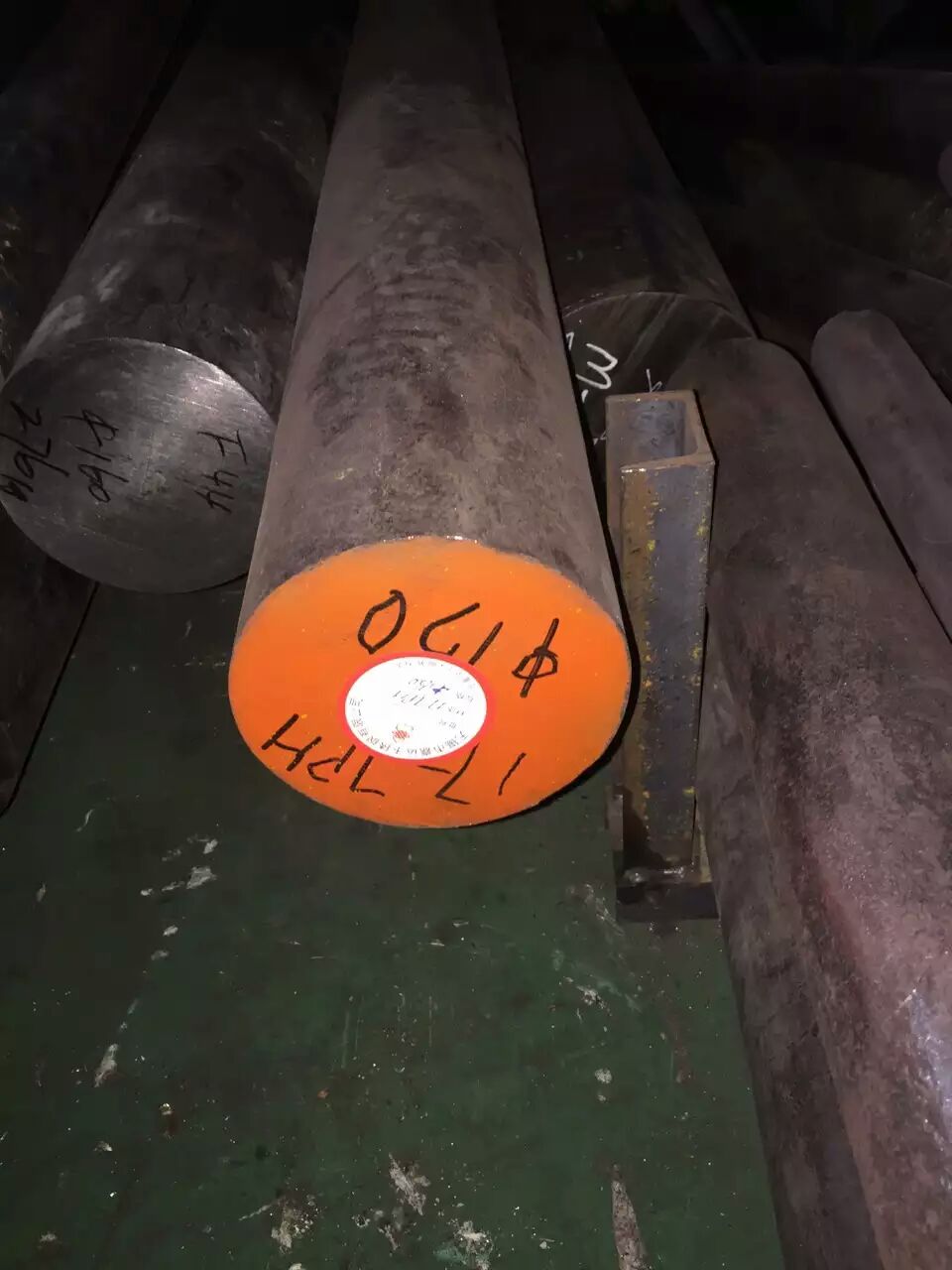

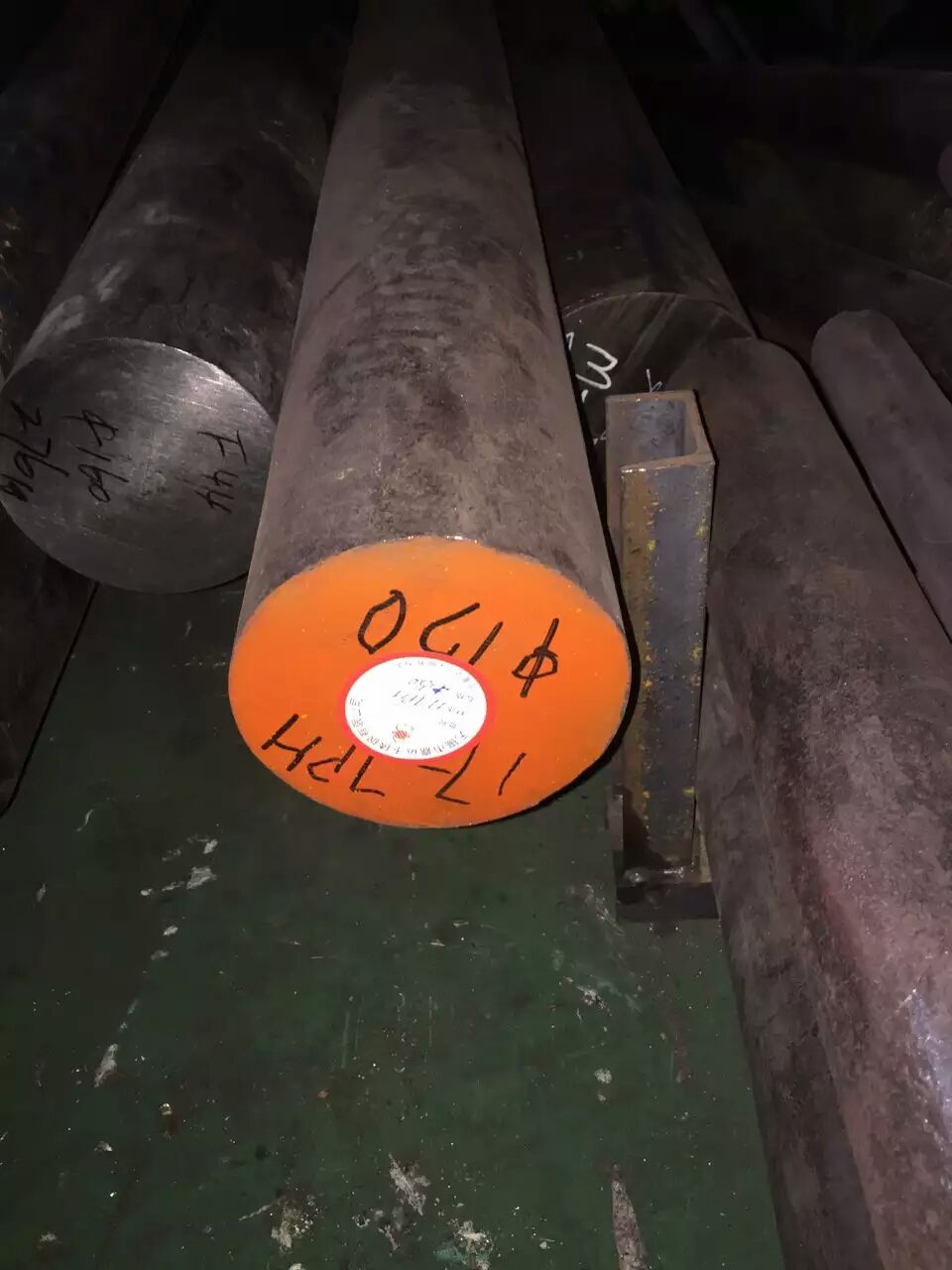

sus630 17-4ph stainless steel round bar

Product Description:

sus630 17-4ph stainless steel round bar

17-4ph stainless steel bar Aisi 630 UNS S17400 SUS630 1.4542

|

17-4PH (630 stainless )- You choose !! | |

|

1. Diameter: |

Ø1'', Ø2'', Ø2.5'', Ø3'', Ø3.5'', Ø4'', Ø4.5'', Ø4.5'', Ø5'',Ø6'', Ø7'', Ø8'' |

|

2. Length: |

3m, 4m, 5m, 6m, 7m...as per clients' requirement |

|

3. Standard: |

ASTM A564 |

|

4. Diameter tolerance: |

H9, H11, H13, K9, K11, K13 etc…as per clients’ request etc |

|

5. Length: |

0/+50mm |

|

6. Surface: |

Bright (CNC turning, peeled, polished, centerless grinding), or black. |

|

7. Finishing: |

Solution treated + age hardening heat treated ( H900, H1100, H1150 etc ) |

|

7. Application: |

Propeller shaft, boat shaft, pump shaft etc |

|

8. Chemical composition: |

C:≤0.07, Si:≤1.0, Mn:≤1.0, P:≤0.04, S:≤0.03, |

|

|

Cr:15.0~17.0, Ni:3.0~5.0, Cu:3.0~5.0 Nb: 0.15~0.45 |

|

9. Certificate: |

ISO, TUV, Mill Test Certificate |

17-4 Precipitation Hardening also known as Type 630 is a chromium-copper precipitation hardening stainless steel used for applications requiring high strength and a moderate level of corrosion resistance. High strength is maintained to approximately 600 degrees Fahrenheit (316 degrees Celsius).

General Properties

Alloy 17-4 PH is a precipitation hardening martensitic stainless steel with Cu and Nb/Cb additions. The grade combines high strength, hardness (up to 572°F / 300°C), and corrosion resistance.

Mechanical properties can be optimized with heat treatment. Very high yield strength up to 1100-1300 MPa (160-190 ksi) can be achieved.

The grade should not be used at temperatures above 572°F (300°C) or at very low temperatures. It has adequate resistance to atmospheric corrosion or in diluted acids or salts where its corrosion resistance is equivalent to Alloy 304 or 430.

| Applications | Standards |

|

|

Corrosion Resistance

Alloy 17-4 PH withstands corrosive attacks better than any of the standard hardenable stainless steels and is comparable to Alloy 304 in most media.

If there are potential risks of stress corrosion cracking, the higher aging temperatures then must be selected over 1022°F (550°C), preferably 1094°F (590°C). 1022°F (550°C) is the optimum tempering temperature in chloride media.

1094°F (590°C) is the optimum tempering temperature in H2S media.

The alloy is subject to crevice or pitting attack if exposed to stagnant seawater for any length of time.

It is corrosion resistant in some chemical, petroleum, paper, dairy and food processing industries (equivalent to 304L grade).

Contact Us

Name: Gao Ben

Tel: 0510-88688870

Fax: 0510-88680060

Add: Chun Xing Industrial Area,Youyi Road,Xishan District,Wuxi City,China

Email: gaoben2012@hotmail.com

MSN: gaoben2012@hotmail.com

Skype: benwallace2012

- Copyright © 2011 Wuxi City Ge Ming Sheng Steel Trading Co.,LTD All Rights Reserved. Powered By 020el